2023 will be a year of efficiency: "How do I achieve more with existing resources" or "- the same with fewer resources"? These are questions that are currently on the minds of many companies. Value stream analysis offers a solution by aligning organizations better with customer needs and optimizing value creation.

But first things first - what is a value stream anyway?

What is a value stream?

A value stream (do not confuse with " value chain"!) refers to the flow of work through an organization, starting with the idea or customer request and ending with the finished delivery/problem solving for the customer. Here we look at the flow from the customer's point of view - From "concept to cash".

Why should I bother?

value streams are a way of looking at processes which help us as a company to work more efficiently and to better align our company with customer needs. Value streams thus represent a way of optimizing value creation in companies. Appropriate measures can often drastically reduce processing times for customers without creating additional work in the organization.

The idea of the value stream comes from the field of "Lean Thinking", which is about creating customer-centric value as efficiently as possible. If you analyze value streams in your own company, you quickly realize that the organization/existing processes are not optimally set up to deliver results as efficiently as possible and in the shortest possible time from start to finish. In order to improve this, we deal with value streams, or value stream management (VSM). In other words, value stream management allows our company to become faster, more efficient and more customer focused, so that we can react faster to change, deliver results more efficiently to the market and gain an advantage over the competition.

Note: Since value streams work across teams, departments or even companies, this topic is usually located at least at the middle management level or above. In this article we are explicitly not talking about a local improvement in a team, but an overarching perspective that optimizes our company as a whole.

Value stream Management consists of three simple steps:

- Identify value streams in the company

- Derive and prioritize improvement potentials

- Continuously manage and optimize the value stream

This article will primarily focus on identifying value streams, as value stream based organizational models are beyond the scope.

How to identify a value stream?

There is a recommended representation for this - the so-called value stream Mapping, which I would like to briefly introduce here. If you want to learn more about it, I recommend reading the book "value stream Mapping" by Karen Martin.

To make it easier to understand the principle, let's imagine a pizzeria that takes orders by phone, makes them and then delivers them to its customers.

- The first step of value creation is the customer's phone call, which triggers the subsequent steps:

- The note is carried to the kitchen after the conversation

- There a kitchen assistant takes the note and brings it to the next free pizza baker

- The latter topples the pizza and passes it on to the baker responsible for the oven

- This one guards the pizza until it is ready and puts it in a box

- This box will be handed over to the next free delivery person together with the address

- The pizza is delivered to the customer.

Now we have identified all the steps of the value stream for our customer. (Note that I left out some more steps like payment for the sake of simplicity here)

How do I measure value streams? - Waiting times and error rates in the process

Next, we analyze how long each process step takes and how long the actual work in this step takes (PT = Process Time (actual work) , LT = Lead Time (total duration) - If the topping of the pizza takes a total of 10 minutes, the Lead Time is 10 minutes. However, in these 10 minutes, the pizza baker only worked on this pizza for 2 minutes, because the pizza had to wait 8 minutes for the "turn". In this case, the "Process Time" is 2 minutes. Let's do this for our example:

- Customer orders via telephone and an employee notes down the order and delivery address on a piece of paper (LT = 5 min, PT = 1 min)

- The note is carried to the kitchen after the interview (LT = 1 min, PT = 1 min).

- There, a kitchen assistant takes the slip and brings it to the next available pizza maker (LT = 10 min, PT = 1 min).

- The latter topples the pizza and passes it on to the baker responsible for the oven (LT = 10 min, PT = 2 min)

- The latter guards the pizza until it is ready and puts it in a box (LT = 10 min, PT = 7 min)

- This box is transferred to the next free delivery person with the address (LT = 5 min, PT = 1 min)

- The box is delivered to the customer. (LT = 20 min, PT = 5 min)

If we now add these values, we find that it takes a total of 61 minutes for a pizza to be delivered to our customer, even though "only" 18 minutes are effectively spent working on a pizza.

In complex scenarios in industry, these numbers are often much further apart than in our simple example.

The next step would be to analyze what the error rate is at each step, writing down how much of the work getting handed over to this step is correct (between 0 and 100%).

Once we have analyzed the lead times, the efficiency (PT/LT), and the error rate, we have a very clear picture of our value stream as well as the bottlenecks and potential for optimization.

With these figures, we can now derive further actions to sustainably improve our value creation for our customers.

A first step would be to further optimize the process flow - especially at steps where waiting times or the error rate are very high.

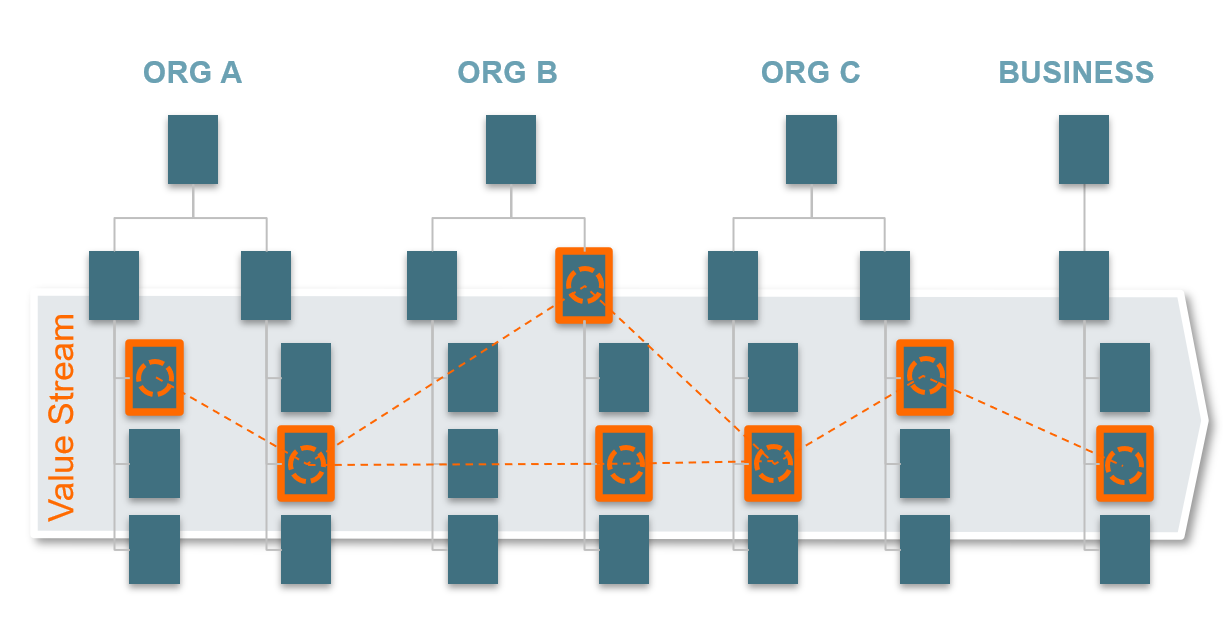

Another step is to think about whether our company is properly structured for value stream processing. What would happen if all employees in a value stream also worked together directly in one team instead of having the value stream spanning multiple teams? Because often a value stream runs horizontally in a vertical (hierarchical organization) - see the following graphic.

As you can see, value stream Mapping is a simple tool to align a company sustainably with customer needs and to improve value creation. It is not uncommon that the result is a reduction of lead times by 50% or more - with the same level of resource utilization!

Continuing thoughts

Value stream considerations and optimization are a management task that allows companies to better align with strategy and customer needs while making the best use of existing resources.

The idea of optimizing the value stream through a system can be found in almost all agile methods (e.g. Scrum, Kanban, SAFe, etc.) - value stream Management takes this effective and proven method one level higher to optimize the company holistically and align it with customer needs. This is often where the greatest potential for improvement can be found, but also the highest resistance, as value stream optimizations often entail a change in the organization.

However, aligning the organization with value streams also brings a great many benefits, such as shorter time to market, more effective use of resources, and an overall better customer-focused company whose organizational model drives value creation, not slows it down.

There are various models for this; SAFe maps these value streams, for example, in so-called "Agile Release Trains" and "Solutions". The important thing here is that you can also start with small steps. For example, people in a hybrid organization can be assigned to the value streams and the previous line organization remains in place for the time being.

In a later step, the old line organization can then be completely dissolved (or changed to a more fitting one) when the advantages of an organization oriented to value streams become sustainably apparent. In this way, a higher level of commitment can often also be achieved among those involved, which simplifies such a fundamental change.